Journal of Oil Palm Research (ELAEIS Special Issue), p. 13-33

BIODEGRADATION OF SURFACTANT IN THE ENVIRONMENT : A REVIEW

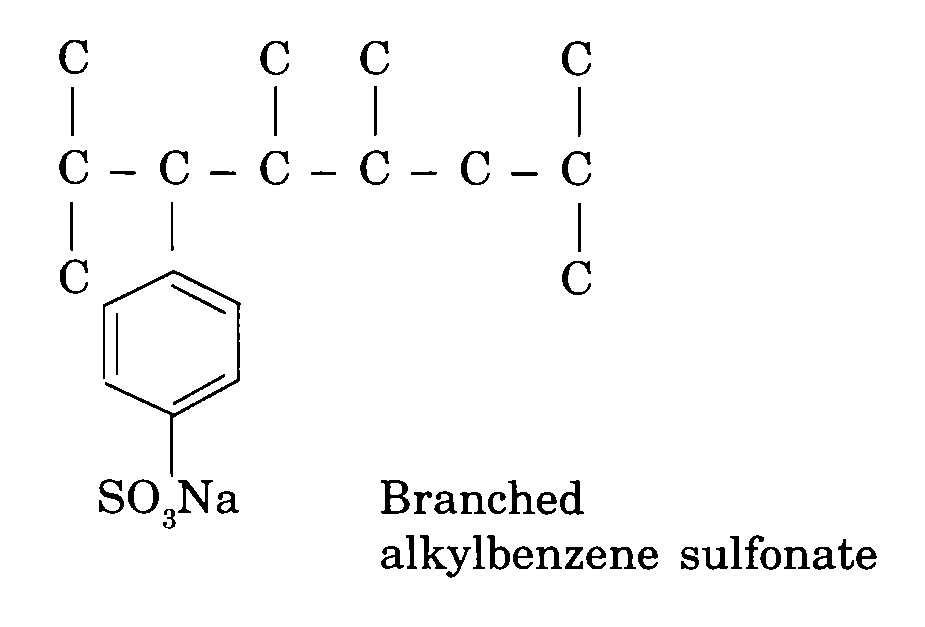

Development of branched alkylbenzene sulfonate (BAS) The replacement of soap with surfactants achieved importance during World War II when oils and fats were in short supply and their replacement became technically and economically feasible (Swisher, 1987). BAS, a synthetic surfactant derived from petrochemical, was the most widely used surfactant during 1950s and early 1960s because of its excellent detergent properties, its low cost and attractive physical properties of its formulation (Hashim et al., 1989). BAS manifests several advantageous characteristics such as good cleaning ability, good solubility and good foaming power. After a few years, the changeover was complete and BAS became the major surfactant used, first in the U.S. and later around the world.

BAS contains a highly branched carbon backbone linked to a sulfonated benzene ring.

Alkylbenzene sulfonate is attacked by microorganisms through the alkyl chain, not through the sulfonate group or the benzene ring (Nielsen et al., 1985). In the case of BAS, the alkyl chain is resistant to microbial attack due to the highiy branch hydrocarbon chains. Microorganisms are deficient of enzyme systems that can attack and biodegrade such highly branched alkyl chains when they are attached to a benzene ring, thus posing problems in the biodegradation of BAS. BAS began to be noticeable in waste waters, treated sewage and receiving waters because they retained their foaming properties in natural waters at concentrations around 1 ppm (Swisher, 1987). However, certain bacteria are able to degrade BAS up to 60% during the primary and secondary treatment processes. However this degradation is slow and consequently, measureable amounts (ppm) are present in treatment plant effluents and these normally enter water systems. In other words, BAS does not undergo complete biodegradation and persists in the environment.

KEYWORDS:* Palm Oil Research Institute of Malaysia,

P.O. Box 10620, 50720 Kuala Lumpur, Malaysia.