Journal of Oil Palm Research Vol. 33 (1) March 2021, p. 64-73

PERFORMANCE EVALUATION OF A MOTORISED PALM OIL EXTRACTOR WITH QUALITY ASSESSMENT OF THE PALM OIL EXTRACTED IN COMPARISON WITH A MANUAL VERTICAL PRESS

DOI: https://doi.org/10.21894/jopr.2020.0096

Received: 31 May 2019 Accepted: 14 February 2020 Published Online: 4 November 2020

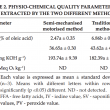

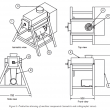

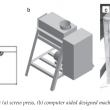

Traditional methods of palm oil extraction from palm fruits (Elaeis guineensis) produce low quality and quantity of oil. This study sought to design, construct and test a motorised palm oil extractor with evaluation of the oil extracted in comparison with a manual vertical press. The performance parameters tested were oil extraction ratio (OER), oil extraction efficiency (OEE), machine discharge efficiency (MDE) and oil extraction losses (OEL) while the tested physio-chemical parameters were free fatty acids (FFA), iodine value (IV), saponification value (SV) and peroxide value (PV). There were significant differences (p0.05) in OER (16.20 and 13.53), OEE (77.13 and 64.44) and OEL (18.30 and 24.76) while the MDE (81.70 and 73.13) were not significantly different (p0.05) for the motorised and vertical press, respectively. No significant differences were observed for IV and SV while FFA showed significant differences (p0.05). The PV was not detected for both methods. A motorised palm oil extractor produced oil of higher uality and had higher performance efficiencies as compared to the manual vertical press. The novelty of this work was in producing an efficient euipment that is affordable to a smallholder farmer which extracts palm oil of high quality.

FIGURES & TABLES:

* Department of Agricultural and Biosystems Engineering,

School of Food Technology Nutrition and Bio-Engineering,

College of Agricultural and Environmental Sciences,

Makerere University, P.O. Box 7062,

Kampala, Uganda.

E-mail: kiggundu@caes.mak.ac.ug