Journal of Oil Palm Research Vol. 33 (3) September 2021, p. 458-472

QUALITY IMPROVEMENT OF PALM KERNEL CAKE AS BROILER FEED USING PRE-CLEANING SYSTEM

DOI: https://doi.org/10.21894/jopr.2020.0112

Received: 10 June 2020 Accepted: 11 October 2020 Published Online: 14 December 2020

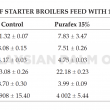

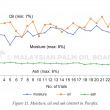

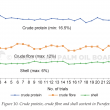

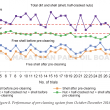

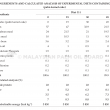

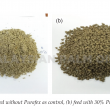

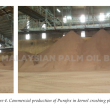

The use of palm kernel cake (PKC) in broiler feed is limited due to high fibrous material contributed mainly by dirt and shell, exceeding 6%. The fibrous component consists of mainly insoluble mannosebased polysaccharides which is not suitable for monogastric animals such as poultry and swine. This study highlights the development of a pre-cleaning system consisting of three-stage winnowing columns to reduce the shell content in kernel by less than 4% prior to oil extraction. In this study, the palm kernels received from 21 palm oil mills were subjected to dirt and shell content analysis. To produce palm kernel with low shell content, the pre-cleaning system was optimised. Further analysis on nutrient values was also carried out for premium grade PKC produced, also known as Purafex, from the clean kernels of low shell content (<4%) after pre-cleaning. A feeding trial was carried out to study the effect of different Purafex inclusion in the dietary treatment on the broilers performance. Results showed that the dirt and shell contents in the kernels varied from 3.48%–5.18%. The nutrient values and quality of Purafex conformed to that of standard specifications by Malayan Edible Oil Manufacturers’ Association (MEOMA). Reduction of shell and fibre in kernel reduces the crude fibre in Purafex from ≥15% to ≤12%, which is far below the fibre in commercial PKC, thus making it digestible for monogastric animals. Better performance in terms of body weight gain (BWG) and feed intake (FI) were exhibited when 15%–30% Purafex were included in feeding trials compared to those of 45% inclusion.

KEYWORDS:FIGURES & TABLES:

* Malaysian Palm Oil Board,

6 Persiaran Institusi, Bandar Baru Bangi,

43000 Kajang,

Selangor, Malaysia.

E-mail: rohaya@mpob.gov.my