Journal of Oil Palm Research Vol. 33 (4) December 2021, p. 678-688

THE EFFECT OF MICROWAVE TREATMENT AND DELAYED HARVESTING ON OIL PALM FRUITLETS (Elaeis guineensis) OIL QUALITY

DOI: https://doi.org/10.21894/jopr.2021.0015

Received: 17 November 2020 Accepted: 29 January 2021 Published Online: 20 April 2021

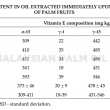

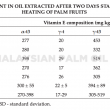

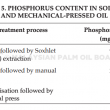

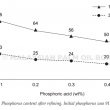

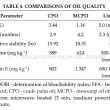

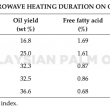

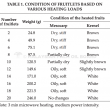

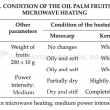

Conventional palm oil mill practice not only processes unwanted empty bunches in sterilisation stage but also produces large amount of wastewater. The oil extraction rate (OER) of the mill is affected by the quality of the oil palm fresh fruit bunches (FFB), which may consist of unripe fruit with less oil content, and uneven distribution of steam throughout the bunches during sterilisation. Besides the FFB, oil palm mills also process loose fruits either collected from the plantations or detached during FFB transportation to the mills. As these loose fruitlets are void of the stalk and core of the bunch, processing them in the same way as FFB is not cost effective. The objective of this study was to carry out processing of fruitlets using microwave, followed by solvent extraction. Loose fruitlets detached in plantations usually come from the outer layer of bunch which contains more oil compared to the inner layer. The following methodology was adopted in this study: 1) optimisation of load per batch for microwave processing of fruitlets, 2) optimisation of microwave heating parameters, and 3) processing of fruitlets detached from the same bunch over 21 days. Fruitlets were sterilised via microwave (2.4 GHz, 900 W, medium power) and its oil is extracted by n-hexane. Optimum load of 170-220 g fruitlets per batch with 3 min heating left the fruitlets to be well conditioned, i.e., softened mesocarp and unburned kernel. The fruitlets get heated rapidly by microwave due to instantaneous dielectric heating effect of moisturised materials. Quality of oil extracted from fruits detached from the same bunch collected over 21 days was investigated. Free fatty acids (FFA), deterioration of bleachability index (DOBI), and oxidative stability of the oil was found to have reduced from 1.3%, 4.32 and 15.18 hr to 6.5%, 0.86 and 5.28 hr, respectively.

KEYWORDS:FIGURES & TABLES:

1 Malaysian Palm Oil Board,

6 Persiaran Institusi, Bandar Baru Bangi,

43000 Kajang, Selangor, Malaysia.

* Corresponding author e-mail: numan@mpob.gov.my